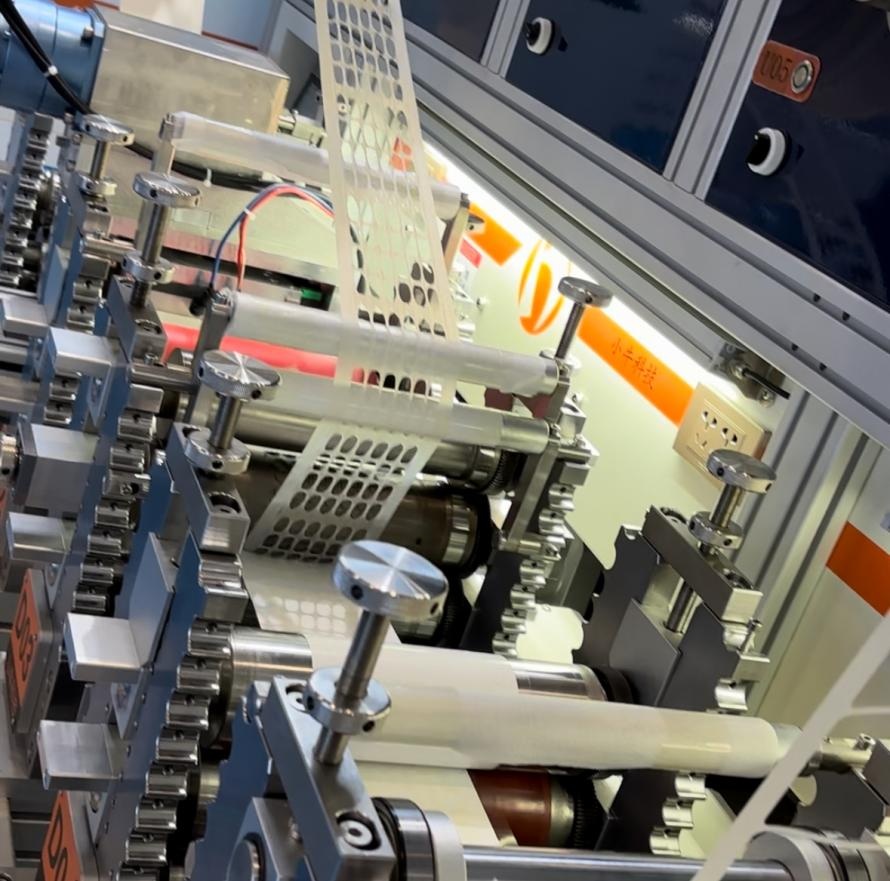

A rotary die cutter (cutting machine) is a machine used to cut, crease, perforate, or kiss-cut materials by passing them between a rotating cylindrical die and an anvil cylinder. The die has raised cutting rules or etched patterns that apply pressure to the material as it passes through the nip point, creating the desired shapes or lines.

Machine applications

Machine advantages

Deviation adjustment with visible data buttons for convenient and precise adjustment.

07

Machine Specs

| Model | X6 | X8 |

|---|---|---|

| Qty of Stations | 6 x 1kw servo motors | 8 x 1kw servo motors |

| Max. Material Width | 250mm | 250mm |

| Max. Material Roll Dia. | 450mm | 450mm |

| Max. Speed | 60m/min | 60m/min |

| Material Shaft | 0.75kw servo motor, x12 | 0.75kw servo motor, x16 |

| Web Aligner | x1 | x1 |

| Conveyor Belt | 500mm+1000mm | 500mm+1000mm |

| Knife Set Suggested | x3 | x4 |

| Cantilever | x1 | x1 |

| HMI Screen | 15″ MCGS made in China | 15″ MCGS made in China |

| Rated Power | 17.5kw | 21kw |

| Safety Mechanism | Safety rope | Safety rope |

| Input Power | 380V or custom | 380V or custom |

| Illumination Lamp | x2 | x2 |

| Input Air Source | ≥0.7MPa | ≥0.7MPa |

| Controller | Omron | Omron |

| Dimensions | 3160*1320*2100mm | 3660*1320*2100mm |